Articles and Q&A about LED promotional trucks

Here’s what we know.

After decades of manufacturing and feedback from an army of Spark truck owners, we still learn something new every day. We’ve always shared this information to help you get the most from your Spark videotruck.

Send us your success story and we’ll share it here, too.

Frequently Asked Questions For LED Video Truck

How bright are the screens? Can you see them in the daytime?

The digital LED screens are as bright as most roadside digital billboards.

Brightness levels are often quoted in candelas per square meter or NITs (the terms are interchangeable). An ordinary TV has a brightness level of approximately 350 – 500 cd/m2. The outdoor screens used at your bank’s ATM or the fast food drive through measure approximately 1500 cd/m2. Spark LED displays have a brightness level of between 5500 and 6500 cd/m2, depending on black or white SMD technology.

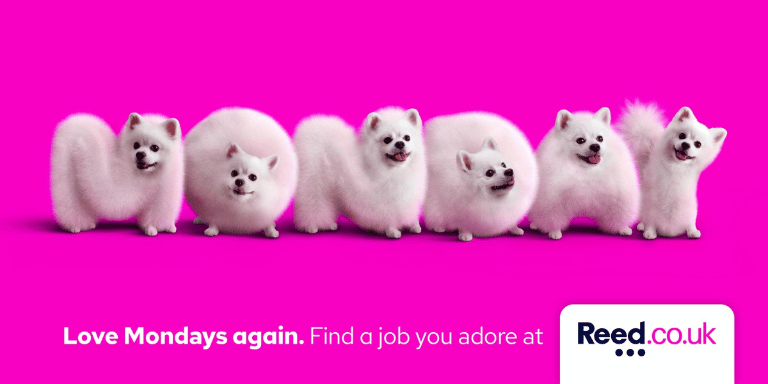

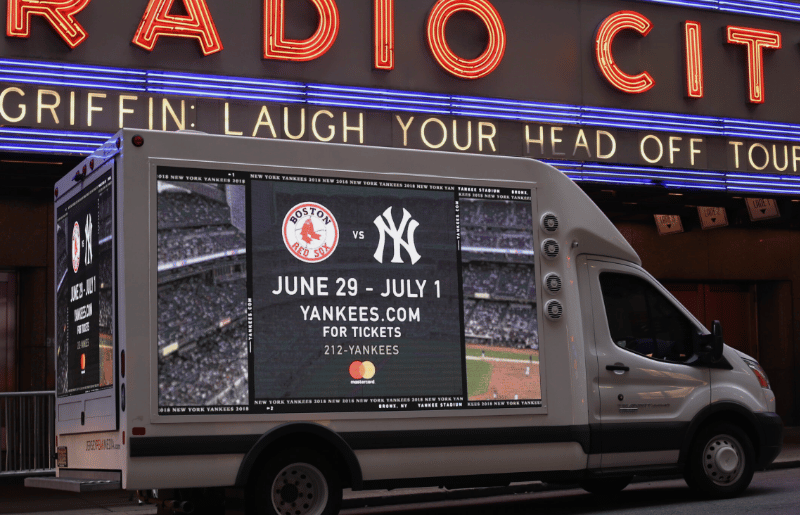

Take a good look at the photos and especially the video clips on this web site. You’ll notice that almost all of the photos are taken on fully sunny days. This is intentional, to demonstrate the visibility of the Spark LED display systems.

What does "6mm or 4.8mm LED" mean? Is a bigger or smaller number better?

Spark only manufactures displays with a pixel pitch of 3.9mm. It’s the highest resolution available on any LED videotruck you can buy.

The smaller number refers to higher resolution LED screens with more detail. The number actually refers to the distance or “pitch” between the centers of each pixel on the screen. For example, a P3.9 display has thousands of LED pixels, each located 3.9mm from the adjacent pixel.

Roadside billboards and stadium screens often use 20mm LED technology because of the lengthy viewing distance between the display and the viewers. Viewed from the length of a football field, the 20mm or 16mm LED screens look like a big TV, but if you were to stand ten feet away you’d notice that each dot on the screen is as large as your thumb. On a 20mm screen, pixels are separated from each other by almost an inch.

P10 used to be considered state of the art for outdoor LED displays, but recently 4.8mm and even 3.9mm technology has become an affordable option for the best looking outdoor LED display systems. Indoor grade systems have progressed to P3 and even P1.2 technology, but those systems are not suitable or bright enough for outdoor use yet.

Spark’s current truck body lineup uses only P3.9 grade displays because there is a significant difference in picture quality achieved by using higher quality LED modules with more on-screen pixels. More pixels means a richer, more detailed image on our LED screens. Of course, Spark’s LED displays are all manufactured specifically for outdoor use, with super high brightness and integrated contrast shutters.

Can I play video, like TV or movies, on the screens?

Yes. If you’re looking for an answer about the technical ability of the displays to show video, that answer is also yes. However, LED screens are not like a regular TV and they require special components to show live video. That component is called a video processor, and it’s an integrated feature of the Spark Mojo OS — no additional hardware required.

What is a video processor, and why do I need one?

If you own a Spark videotruck, you don’t need one.

A video processor is a special component that scales and formats the video signal from a media player, satellite receiver, DVD player, computer, or video game console and converts it into a format that can be displayed on an LED screen. It is sometimes called a “scaler”. Better quality processors include hardware and software that enhances image quality and also include multiple inputs so you can switch between several different video sources. If you want to show anything other than a slideshow, you’ll want a video processor.

Spark incorporates all of the functionality of a video processor into the Mojo control software that powers each truck.

Where do the LED screens come from?

The LED displays in Spark trucks are a unique Spark-designed and Spark-only product. We start with a demanding specification for size, brightness, contrast and power consumption. Then we prototype units in Alabama and refine the design with attention to ease of maintenance. We partner with suppliers in Asia who are capable of producing the unique Spark outdoor LED components.

During the LED manufacturing and assembly process, we send a team of inspectors who test and evaluate every component prior to shipment. After inspection, the displays are packed in protective flight cases to ensure everything arrives in perfect condition.

Is there a protective window covering the screens?

No.

There are two reasons why there is no clear window over the display screens. First, putting the screens behind a window would introduce glare and reflections on both sides of the glass. Anything that’s placed in-between a digital display and viewers reduces image quality. Secondly, about ninety percent of the heat generated by an LED display is created by the individual LED pixels. With no window, we are able to let the heat dissipate off the front of the screen. If the display were behind a window, the interior of the truck body would become excessively hot.

Spark uses special LED display systems that are designed for outdoor use and are waterproof.

Can I protect the screens from vandalism?

The outdoor grade LED displays are similar to the displays you’ve seen at concerts and football stadiums, except much higher quality. They can withstand all weather conditions, but are no more impervious to vandalism than the rest of the vehicle. Nonetheless, over the last dozen years, we have received reports of only two customers’ trucks experiencing any incidence of vandalism.

How does one deliver ad content to the screens?

Regular (non moving video) ads are created in JPG format and are uploaded from your laptop computer, phone or tablet into the Spark Mojo software.

All Spark trucks include remote administration, which includes a live 4G Internet connection and software that includes the ability to create custom playlists of ads which can be uploaded live to the truck while it is on the road.

What does the body weigh?

The Spark truck body is designed specifically to support and carry the array of digital LED screens mounting in the truck. It is made of aluminum and is up to 3000 pounds lighter in weight compared to other box shape truck bodies (including trucks with screens that have been converted from box trucks).

For example, Spark’s best selling 510 video truck body, mounted on a Ford Transit cutaway chassis has a total curb weight of 6900 pounds. That’s only a few hundred pounds more than a big SUV like a Suburban.

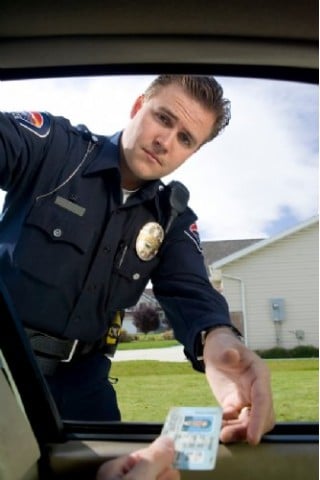

Because the Spark truck weighs less than 10,000 pounds, you won’t need to obtain a USDOT registration number, and you don’t need to stop at weigh stations. Your drivers will not need to carry medical cards, and you can operate the truck with an ordinary drivers license (no CDL required).

How much useful cargo space is available inside the truck body?

Inside Spark digital video truck bodies you’ll find only the power system and electronics for the displays. The rest of the interior space is available for any purpose.

Where does the truck chassis come from? Can I use my own truck?

Spark 4-Series bodies are compatible with almost any pickup truck chassis. Spark 407 and 408 are designed to mount on full-size pickups (like Ford F150). Spark 405 is specifically designed for Jeep Gladiator. Customers may supply their own truck, new or used. Spark is pleased to provide new US-spec Ford F150 trucks for customers, and in that case, the entire transaction is completed through the authorized Ford dealer.

Spark 5-series and 7-series bodies are married to a Ford Transit or Mercedes Sprinter cutaway chassis. Spark 8-series bodies use the Isuzu NPR or Hino 155 chassis.

How is the body made?

Spark truck bodies are manufactured in two stages. First, the bodies are manufactured into a bundle of body components which includes all aluminum body parts, the roof system, the floor and walls. Then the body kits are delivered to one of our facilities where they are assembled and mounted on compatible truck chassis. This process assures that each body is identical quality and if replacement body parts are ever needed, we’re able to assure a complete fit with the original parts.

After the body is assembled on the truck chassis, we move the truck into our final assembly center in Fairhope, Alabama, where the electronics and power system are installed.

Complete Spark Mobile LED Truck Model Lineup

Prices are for the Spark display video advertising truck body only and do not include the price for the truck chassis.