Kinda boxy,but it’s not a converted box truck.

Spark specialty truck bodies are quality, eye catching promotional tools for business.

Since 2002, we’ve continuously upgraded, strengthened, lightened, and improved the exoskeleton truck body platform; working to make it look great, while protecting and supporting an array of LED display screens.

Everything about the unique exoskeleton bodies is intentionally made to be very different from ordinary box trucks. There’s just nothing else like it.

Special

Spark is serious about keeping the “special” in specialty truck bodies. Each videotruck body is sleek, with rounded corners, with no exposed bolts or rivets, with upgraded lighting, and with a custom aerodynamic spoiler.

Lightweight

Spark truck bodies platforms are constructed from a series of custom designed aluminum extrusions. They lock together, forming a full perimeter exoskeleton truck body structure. Super strong, yet lightweight, it doesn’t require any structural steel and is dramatically lighter than other types of truck bodies.

The final curb weight of a Spark videotruck, with its cleverly engineered exoskeleton truck body paltform, is up to 3000 pounds lighter than a converted box truck.

Reducing the overall truck weight leads to greater safety and increased fuel economy.

Curved > Straight

Engineering 101 says if you take two pieces of metal — both the same thickness, one straight and the other curved, the curved piece would be several times stronger than the straight piece. That’s why Spark’s extruded aluminum corner posts and roof railes are curved.

It not only looks great, but it allows us to design structural body members that are simultaneously stronger and lighter weight than body members made from flat or squared off components. It’s why the 18-foot wide side opening of a Spark 818 requires no center support during body assembly, and it’s why a converted box truck’s without Spark’s roof system collapses unless it’s propped up with wooden poles after the side walls are cut out.

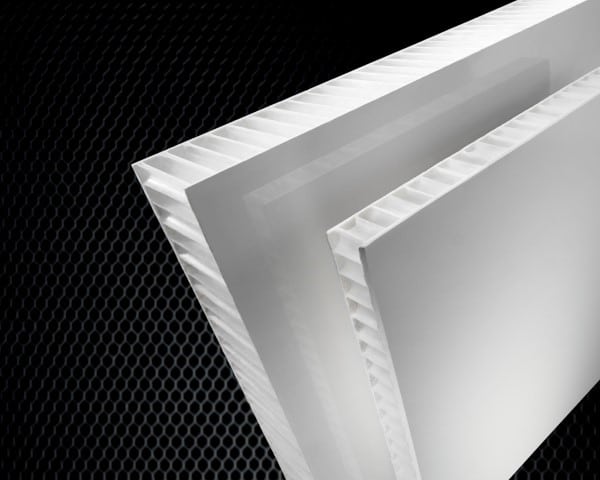

Composite Honeycomb Floor

You might not pay much attention to the floor inside a commercial truck body, but we do.

The most common floor material used in a delivery truck is either plywood sheets or wooden planks. One’s lighter, the other’s tougher. Over time, either can rot from anywhere water may intrude. Both require undercoating.

Spark exoskeleton truck bodies platforms feature a smooth white floor system. It’s made from heavy duty one-inch thick polypropylene honeycomb core fiberglass reinforced panels. It’s bonded to aluminum crossmembers below, leaving the surface smooth and free of any mounting holes. Best of all, it’s extremely tough, can never corrode, rust, or rot, doesn’t need to be undercoated, and it just looks great.

Safety

New Spark bodies, once mounted on a suitable truck chassis, are deemed “complete” accounting to NHTSA standards — even without the additional rigidity provided by the LED display system. They can be registered, and are fully authorized to be operated on any local, state or federal road.

Pictured: Spark 407 body mounted on Ford F150 pickup chassis.

Spark LED Technology

Spark’s P3.9 LED display technology delivers high brightness, low power consumption, and is designed for the harsh commercial mobile environment.

Spark Mojo Cloud-Based Control System

Control one or many Spark videotrucks from anywhere using Spark Mojo software for Windows. Coming soon: Native Mojo apps for iPhone and Android devices.

Spark Hybrid and EV Power Options

Only Spark offers a choice of generator power, hybrid power, or all battery electric power for the LED display system.